Infinity Molding & Assembly, Inc. is a custom plastic injection molder specializing in difficult geometries and engineering grade thermoplastics incorporating high heat resins requiring hot oil systems for mold temperature control. Our customers cover the medical device industry and many areas of the automotive industry as well as some consumer goods companies. We have been in business since 1982 and are ISO 13485, IATF 16949 and ISO 14001 certified.

Made in America means better quality and delivery. Infinity Molding & Assembly, Inc. is committed to providing the highest quality products and services. We are ISO 13485 certified which makes Infinity a valuable resource for medical device companies of all sizes and IATF 16949 to support our automotive customers. We have the expertise and experience to help companies bring their products to market quickly and efficiently. Have questions? Contact us using the info below, or click HERE for our FAQ page!

Product Quality Assurance

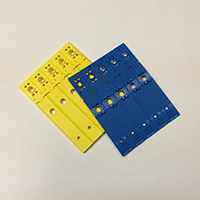

We utilize electronic vision and inspection systems to ensure part quality is maintained

AUTOMOTIVE PARTS MANUFACTURING

High tolerance injection molding meeting or exceeding our customers' exacting standards

CLEANROOM MEDICAL MOLDING

Separate 11,000 square foot ISO Class 8 (100,000) cleanroom manufacturing and white room assembly facility

Infinity Molding Overview

Infinity Featured on "MADE IN THE TRI-STATE"

Infinity Molding & Assembly was featured on an episode of 14 News' "Made in the Tri-State"! The short video, sponsored by First Bank, showcases Infinity's ability to make high precision, high tolerance plastic parts and assemblies for the automotive and medical industries. President & CEO Scott Titzer points out that Infinity's cleanroom facility is the only one of its kind within a 300 mile radius, making it rather unique to the industry. Executive Vice President / CFO Sondra Ash states that Infinity's success is due largely to its employees who are able to perform both individually and in team groups to provide the high quality product Infinity produces.